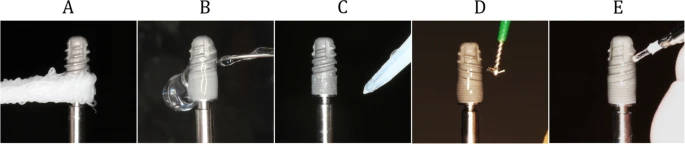

Figure 3. Decontamination methods. a Gauze soaked in saline applied using a sawing motion. b Ultrasonic scaler (SUPRASSON P-MAX, Satelec-Acteon group, Bordeaux, France, power setting: P5, tip: Implant Protect IP3L/R).

Figure 3. Decontamination methods

author: Motohiro Otsuki, Masahiro Wada, Masaya Yamaguchi, Shigetada Kawabata, Yoshinobu Maeda Kazunori Ikebe | publisher: drg. Andreas Tjandra, Sp. Perio, FISID

Serial posts:

- Evaluation of decontamination methods of oral biofilms formed on screw-shaped, rough and machined surface implants: an ex vivo study

- Background : Evaluation of decontamination methods of oral biofilms formed on screw-shaped, rough and machined surface implants

- Materials & methods : Evaluation of decontamination methods on implants (1)

- Materials & methods : Evaluation of decontamination methods on implants (2)

- Materials & methods : Evaluation of decontamination methods on implants (3)

- Results : Evaluation of decontamination methods on implants (3)

- Discussion : Evaluation of decontamination methods on implants (1)

- Discussion : Evaluation of decontamination methods on implants (2)

- Discussion : Evaluation of decontamination methods on implants (3)

- Discussion : Evaluation of decontamination methods on implants (4)

- Discussion : Evaluation of decontamination methods on implants (5)

- Discussion : Evaluation of decontamination methods on implants (6)

- Discussion : Evaluation of decontamination methods on implants (7)

- Discussion : Evaluation of decontamination methods on implants (8)

- Discussion : Evaluation of decontamination methods on implants (9)

- Figure 1. Hard resin splint model carrying 6 implants

- Figure 2. GC Aadva® implant; 3.3-mm diameter, 8-mm length

- Figure 3. Decontamination methods

- Figure 4. SEM analysis of 4 areas. 1 Rough surface—microthread area

- Figure 5. Quantitative analysis of CFU counts on implants

- Figure 6. Comparison of cleansability of each decontamination method

- Table 1 Qualitative evaluation by SEM analysis of micro- and macrothread areas of rough surface implants

- Table 2 Qualitative evaluation by SEM analysis of micro- and macrothread areas of machined surface implants

- Table 3 Quantitative analysis of CFU counts